In order to summarize and promote the successful experience of digital transformation of manufacturing enterprises in Longhua District, further guide and motivate the majority of manufacturing enterprises to accelerate digital transformation, a series of special topics titled "2022 Longhua District Manufacturing Enterprise Digital Transformation Benchmark Cases" have been launched. 39 excellent cases of digital transformation of manufacturing enterprises in the entire district have been selected, aiming to comprehensively showcase their innovative practices and achievements in the process of digital transformation. Through the release and promotion of special case studies, further promote the digital transformation of manufacturing enterprises, accelerate the digital development of industries, and provide useful reference and guidance for the digital transformation of Longhua District and even the whole country.

26th issue

Shenzhen Dingxinsheng Optical Technology Co., Ltd. - Digital Upgrade and Transformation of High Precision Optical Lens Production Equipment

01/Company Introduction

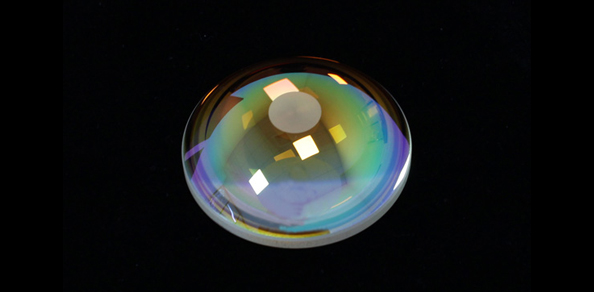

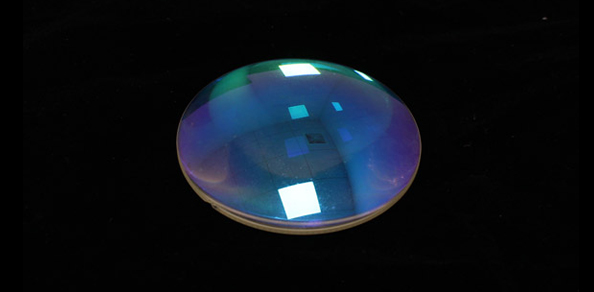

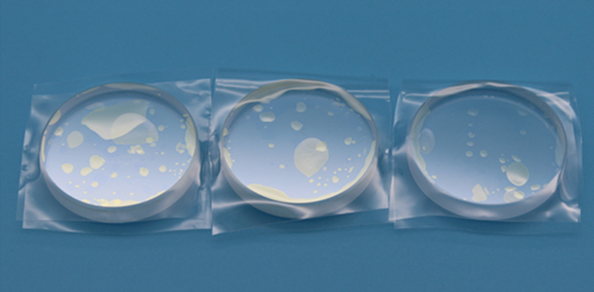

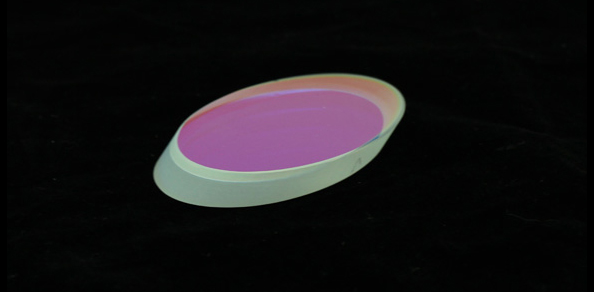

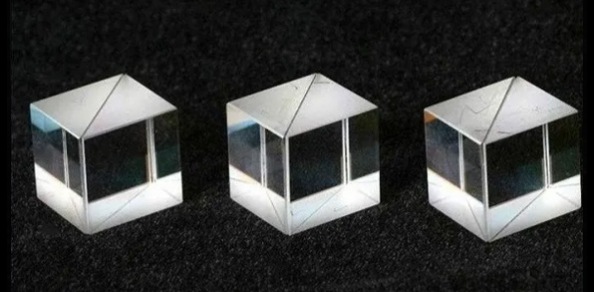

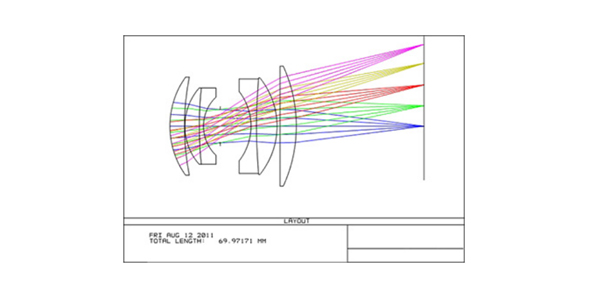

Shenzhen Dingxinsheng Optical Technology Co., Ltd. is a high-tech enterprise specializing in the research and production of precision optical lenses. It was officially established in 2008 and is located in Guanlan, Longhua, Shenzhen. The factory covers an area of 4000 square meters and currently employs around 150 people with a total investment of tens of millions. Dingxinsheng Optics is an optical component non spherical, spherical, and planar lens processing enterprise with a history of more than ten years. The company integrates classical polishing technology and modern polishing technology, and adopts the technology process of virtue for coating. Through continuous exploration and innovation, it has gradually formed its own unique polishing technology and coating technology.

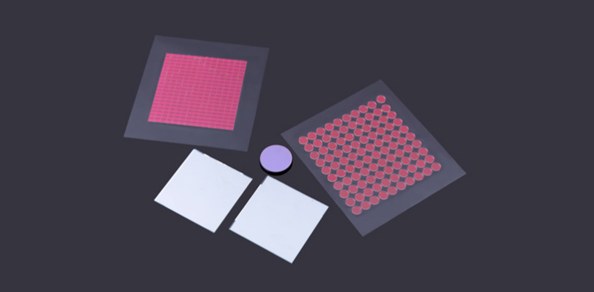

Dingxinsheng Optics has complete processing and testing equipment, most of which are high-end imported equipment, covering processes such as raw material cutting, mold&fixture CNC, cold processing, coating, testing, warehousing, etc., ensuring that the entire product process is completed under strict control of the company, paying attention to details, and ensuring first-class high-quality service to customers.

The establishment of a digital intelligent platform management system and ERP system has achieved the informatization of production process data, systematization of R&D information, intelligent control of key department personnel entry and exit, as well as information-based assessment and remote communication of R&D personnel working hours, and intelligent control of confidentiality departments. By integrating information resources such as research and development, manufacturing, sales, and supply chain, the interconnection of system, equipment, key workstation data, and personnel information has been achieved, realizing digital intelligent manufacturing management.

03/Specific Measures

Introducing advanced CNC equipment from abroad

Purchase advanced CNC milling and grinding machines, CNC polishing machines, and non spherical optical measurement systems from abroad to achieve precise positioning and easy measurement, increase production efficiency by 35%, and improve product yield by 15%.

Customized digital intelligent platform management system

By establishing a digital intelligent platform management system and ERP system, the informatization of production process data, systematization of R&D information, intelligent control of key department personnel entry and exit, information-based assessment and remote communication of R&D personnel working hours, and intelligent control of confidentiality departments can be achieved. Seamless integration of workshop equipment, establishment of control feedback relationships, and improvement of collaborative operation capabilities between workshop personnel and equipment, as well as between equipment and systems.

ERP management system realizes resource integration and sharing

Adopting the EasyHelp ERP management system, it comprehensively covers various business management areas of the company, fully integrates the internal business flow, logistics, capital flow, and information flow, and maximizes the integration and sharing of internal resources of the company.

04/Achieving Results

1. The product quality rate has been increased to a pass rate of 95%.

2. 100% online quality inspection and data traceability.

3. Shorten processing time by 30% and reduce production costs by over 30%.