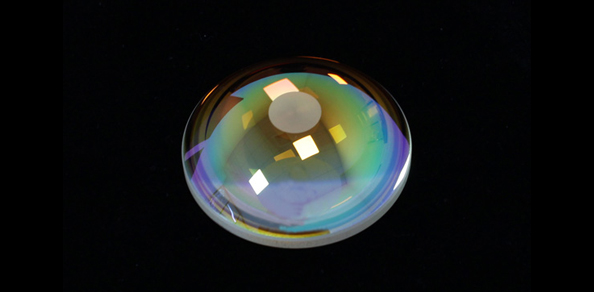

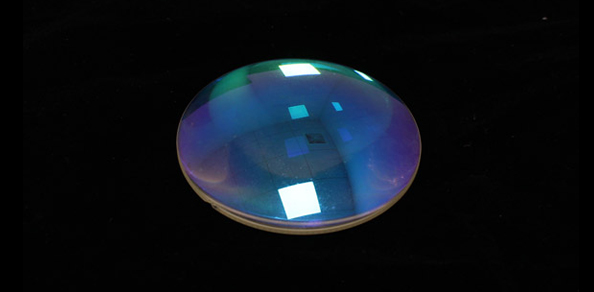

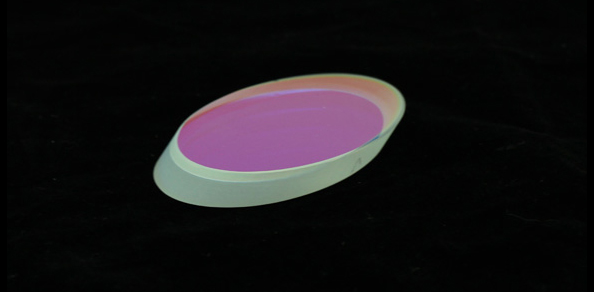

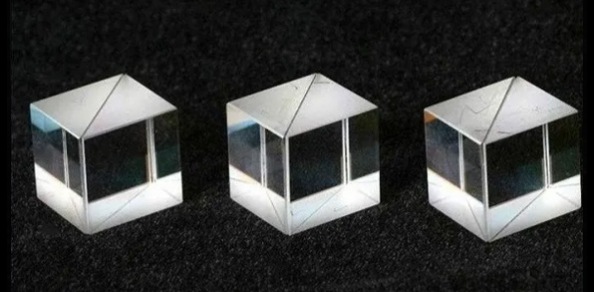

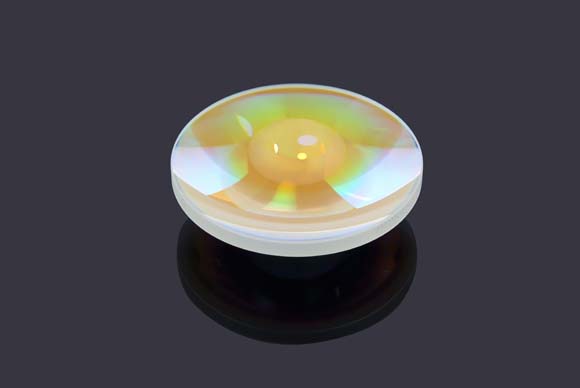

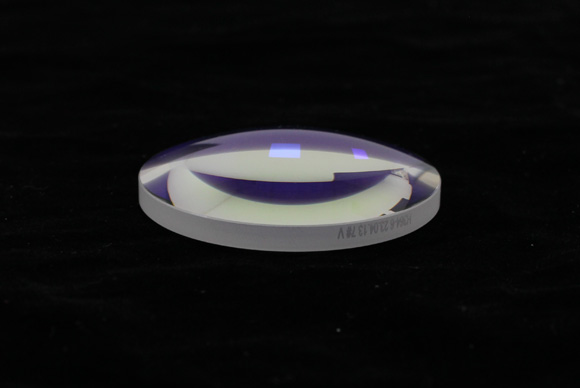

Aspheric Lens Customized design on demand

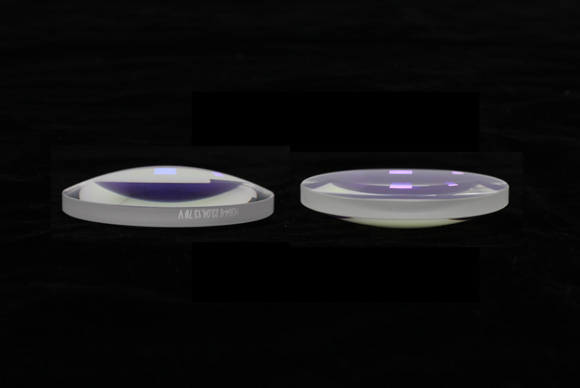

Base: Glass material

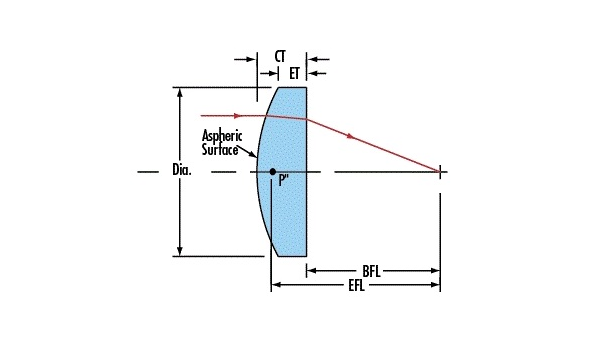

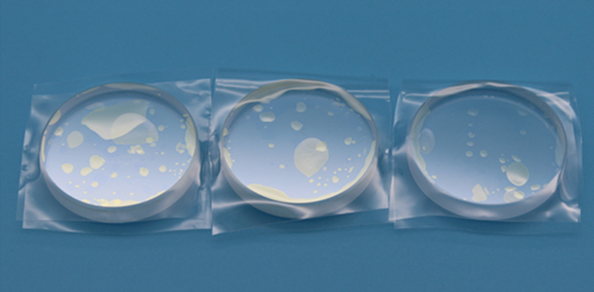

Size range: П† 12- П† 260mm

Surface quality: 20-10

Center deviation (arc seconds): ≤ 5

Center thickness tolerance: В± 0.05

Effective aperture (%):>90

Surface accuracy PV (гЋ›): 0.15

Processing method: CNC

If you have different requirements, please consult customer service!

Consult immediately

Details Introduction

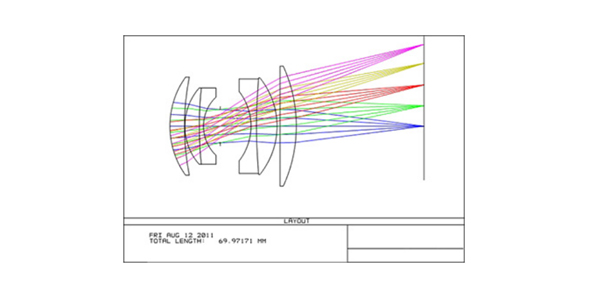

Aspheric Lens have a continuous change in curvature from the center to the edge, with the curvature radius varying with the central axis, in order to improve optical quality and minimize the number of lenses in the lens. Non spherical lenses have unique advantages over spherical lenses in correcting spherical aberration, and have been widely used in optical instruments, focusing imaging, and optoelectronics industries.