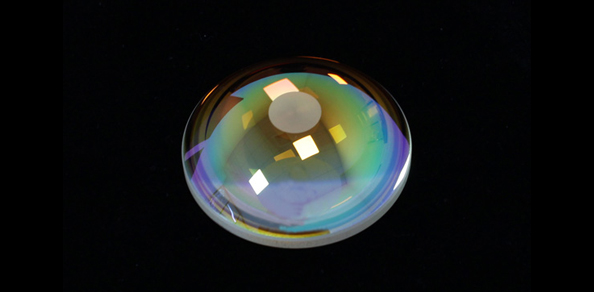

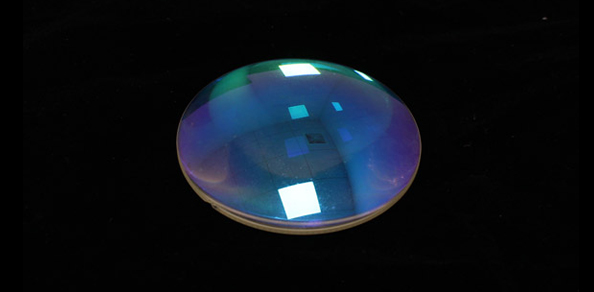

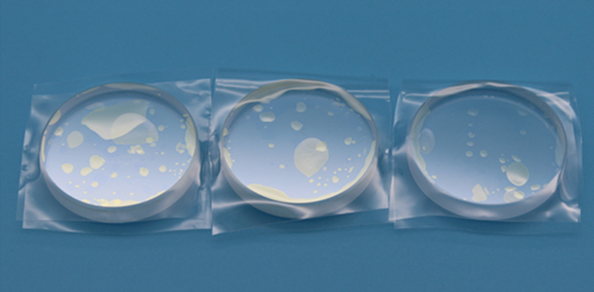

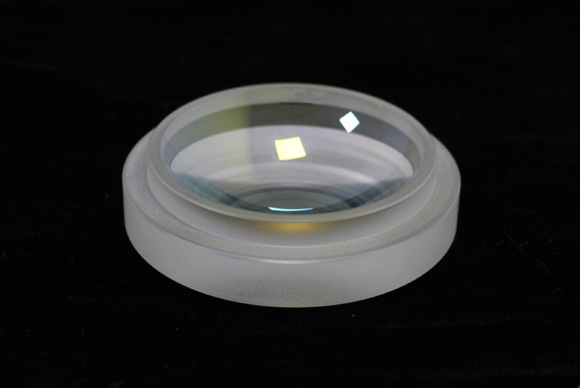

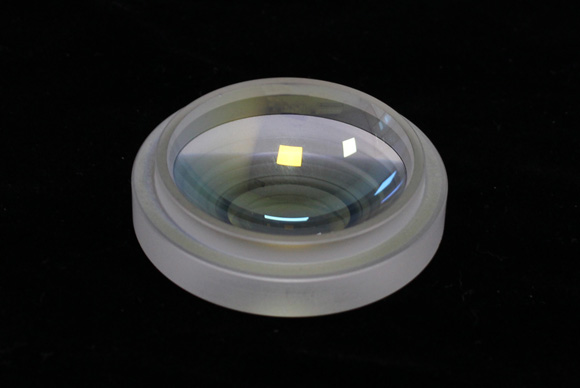

Base: Glass material

Size range: П† 12- П† 260mm

Surface quality: 20-10

Center deviation (arc seconds): ≤ 5

Center thickness tolerance: В± 0.05

Effective aperture (%):>90

Surface accuracy PV (гЋ›): 0.15

Processing method: CNC

If you have different requirements, please consult customer service!

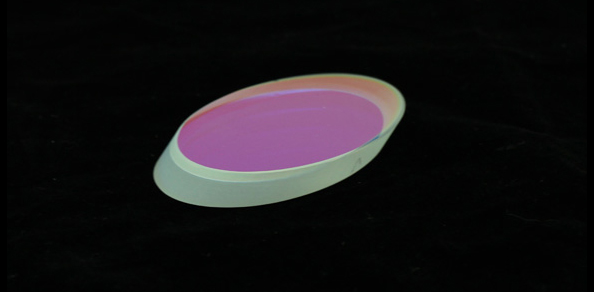

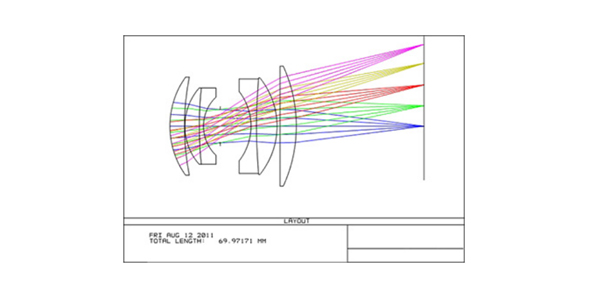

Axial step: Stacked in layers along the optical axis direction, similar to "multi-layer non spherical surfaces", used for segmented optimization of optical power.

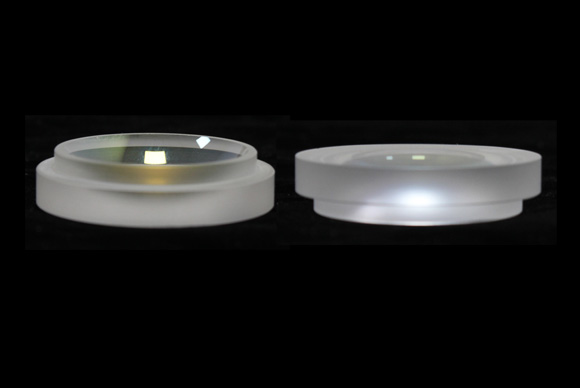

Radial step: Distributed in the form of concentric rings on a non spherical surface (similar to a Fresnel lens but with a non spherical base), reducing the thickness of the lens through annular compression.

Hybrid step: Combining the phase step of diffractive optical elements (DOE) to achieve chromatic aberration correction or multi wavelength compatibility.

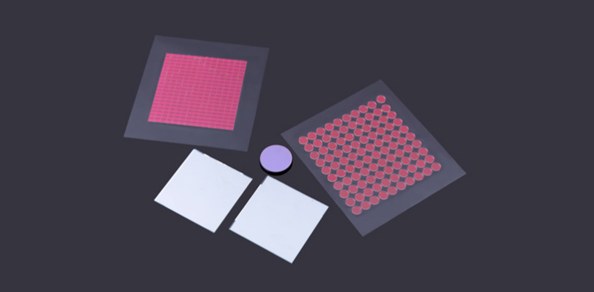

Main application areas

Consumer Electronics

Mobile phone camera: The stepped design compresses the thickness of the lens, assisting in ultra-thin multi camera modules while maintaining high resolution (such as periscope telephoto lenses).

AR/VR near eye display: Lightweight non spherical step lens expands the field of view, reduces the weight of the headset, and enhances the immersive experience.

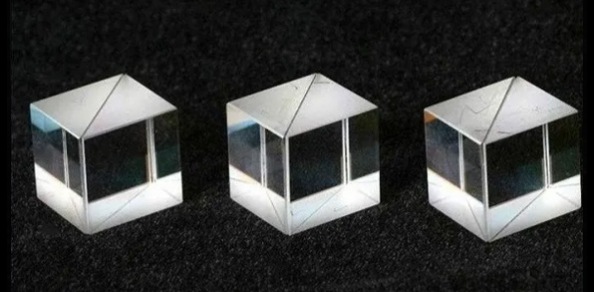

Laser and Optical Communication

Laser collimation/focusing: The stepped structure optimizes the energy distribution of the beam, improving the efficiency of laser processing (cutting, welding).

Fiber optic coupling: Non spherical substrate improves coupling efficiency, step design suppresses echo reflection, and reduces optical loss.

Vehicle mounted and autonomous driving

LiDAR optical system: Lightweight step non spherical lens is used for transmitting/receiving modules to adapt to vehicle vibration environments, improve ranging accuracy and response speed.

HUD (Head Up Display): Combining free-form surfaces and stepped structures, it achieves a large field of view, high brightness projection, and reduces the size of the optical system.

Aerospace and Remote Sensing

Satellite optical payload: The stepped design reduces the weight of the lens and improves the quality of remote sensing imaging by correcting atmospheric distortion through non spherical surfaces.

Space Telescope: Large aperture stepped non spherical main mirror balances lightweight and surface accuracy, reducing launch costs.

Medical and Biological Imaging

Endoscope/microscope objective: The small-sized step lens enhances the flexibility of the instrument, and the multi focus design supports depth of field extension imaging.

OCT (Optical Coherence Tomography): Optimizing the reference optical path and sample optical path with step non spherical surfaces to improve scanning resolution.