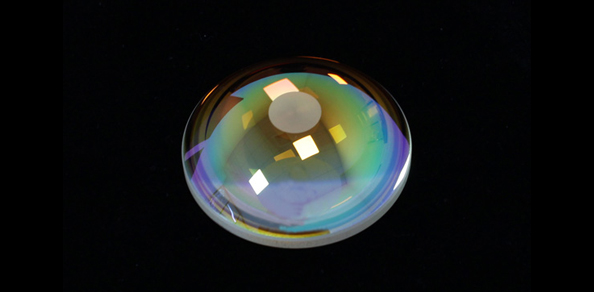

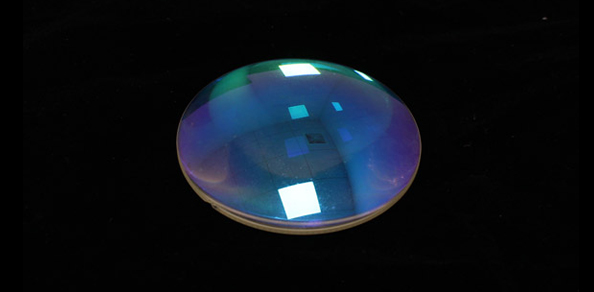

Laser is a single wavelength light source with good coherence performance, which has a wide range of applications in scientific research and industry. Laser optics refers to optical components and devices used in the internal and external optical paths of lasers, such as laser focusing mirrors, reflecting mirrors, beam expanding mirrors, and laser cutting heads. In order to enable friends to intuitively understand the concepts of laser focusing and collimation.

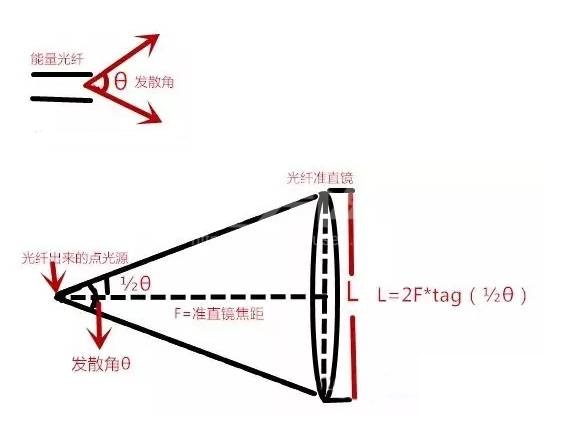

Collimators are designed for point light sources, which we often see in our daily lives, such as matchstick ignition, old-fashioned flashlight bulbs, and lasers coming out of energy fibers. For our industrial laser industry, when we talk about collimating mirrors, we basically talk about the laser coming out of the energy transmission fiber.

What is laser collimation, the difference between laser collimation and laser focusing lens

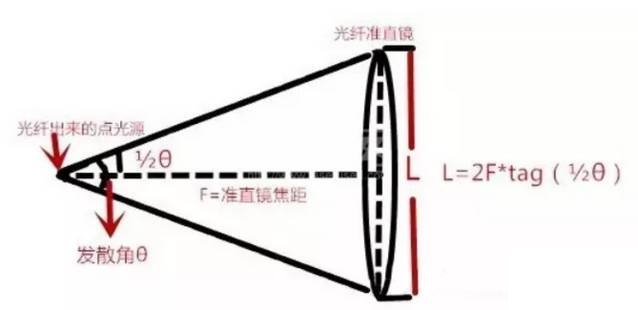

The light coming out of the energy fiber is a point light source with a divergence angle (θ), which can generally be found. If we place this point light source at the focal point of a fiber optic collimator, we know that the light emitted from the focal point of a focusing mirror (which actually reverses the focusing mirror) becomes parallel light after passing through the focusing mirror. Many people ask me what the diameter of the beam coming out after passing through a certain collimating mirror is. Today, I am here to give you the answer, which is 2F * tag (1/2 * θ). If the divergence angle is 10 ° and F=150mm, then the diameter of the beam coming out of the collimating mirror is 2 * 150 * tag (5 °)=26.2466mm. This formula is of reference significance for welding machines to select vibrating mirrors for fiber optic transmission. Continuing on is what industry professionals in the fiber optic cutting machine industry want to know. After passing through the fiber optic collimating lens, the laser enters the focusing lens of the fiber optic cutting machine. According to theory, the focal length of the collimating lens ÷ the focal length of the focusing lens=the ratio of the energy density after focusing to the previous density. For example, the focal length of the collimating lens is 75mm, the focal length of the focusing lens is 150mm, and 75 ÷ 150=1/2. This means that the area of the focused spot after passing through the focusing lens is twice as large as the area of the point light source that just came out of the energy fiber, and the energy density is 1/2 of the original.

What is laser collimation, the difference between laser collimation and laser focusing lens

Someone asked, why do we need to reduce energy density? Isn't it better to concentrate energy density? There are several reasons here:

Firstly, if the focal length of the focusing lens is shorter, the depth of focus of the focusing lens will be shallower, which can easily lead to insufficient depth of cut.

Secondly, the shorter the focal length, the smaller the focal point, and the smaller the cutting seam. A small seam is not conducive to the falling of slag during cutting, resulting in incomplete cutting. So we usually try to use a focal length between 120-150mm as the focusing lens for fiber optic cutting machines. Additionally, there are two reasons why we do not use long focal length collimating mirrors:

Firstly, using a long focal length fiber optic collimator requires a larger lens diameter, which can lead to mechanical design difficulties.

Secondly, using a long focal length fiber optic collimator can cause sensitivity to the focal point of the fiber optic cutting machine during focusing. Once it deviates slightly from the focal point of the collimator, there may be a phenomenon of incomplete cutting. This is why the focus of our general fiber cutting machine is usually between 60-100mm.

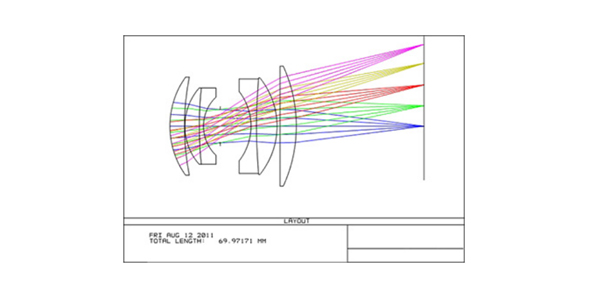

Beam expansion

In practical applications, it is often necessary to expand the laser beam. To achieve this function, at least two lenses are required. Most laser beam expanders adopt a Galilean design, consisting of a combination of positive and negative lenses. Due to its low expansion coefficient and simple, compact structure, the beam expander is widely used. It amplifies the laser beam to achieve a smaller focused spot.

To minimize the difference, it is best to choose this type of plano convex and plano concave lens, and place them facing each other on one side of the plane. Using the central part of the lens can further reduce the phase difference, so choosing a larger size lens can be helpful. This type of beam expansion design is called Galilean beam expansion. The use of two convex lenses with positive focal length can also achieve beam expansion function, known as Kepler style beam expansion, but this design has a longer size.