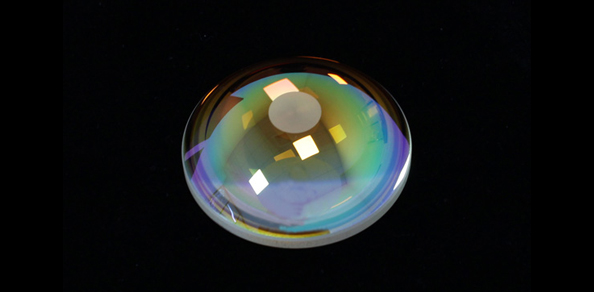

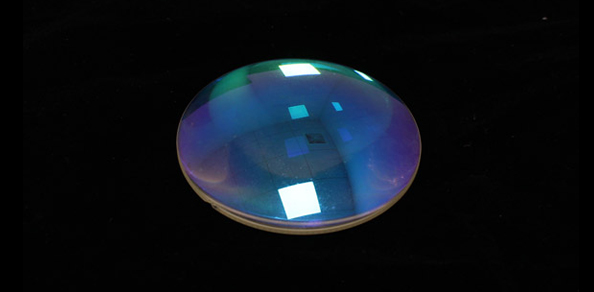

The focusing lens of a laser cutting machine is a consumable item, and it needs to be replaced when it still cannot achieve high cleanliness after multiple cleaning cycles,Ensure the processing efficiency of the laser cutting machine to avoid delaying production.

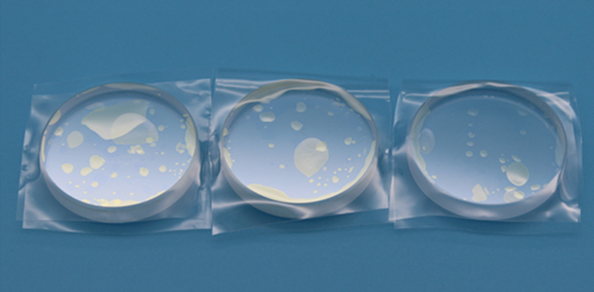

The focusing lens of a laser cutting machine is a relatively precise optical component, and its cleanliness directly affects the processing performance and quality of the laser cutting machine.If the lens selection is improper, it can cause significant laser losses, frequent damage to protective lenses, unstable product quality, and cause serious losses to the enterprise.Although the protective lens of a laser cutting machine is a vulnerable part, in order to improve its utilization and reduce production costs, it can be reused by regularly cleaning the protective lens.

Methods and precautions for maintaining laser lenses:

Generally, it is necessary to check the condition of the focusing lens of the laser cutting machine before use and before and after cleaning.Because most pollutants and surface defects have relatively small sizes, we often need to use magnifying devices when inspecting lenses.In addition to amplifying equipment, sometimes we also need to use a relatively bright beam of light to illuminate the optical surface,Enhance the specular reflection intensity of surface pollutants and defects, making it easier to detect them.

When cleaning the focusing lens of a laser cutting machine, clean wiping paper and optical grade solvents are often used to prevent damage from other pollutants.The wiping paper must be moistened with a suitable solvent and must not be used dry.For the consideration of softness, pure cotton Webril wiping paper or cotton balls, lens paper, and cotton swabs can be used as applicators.

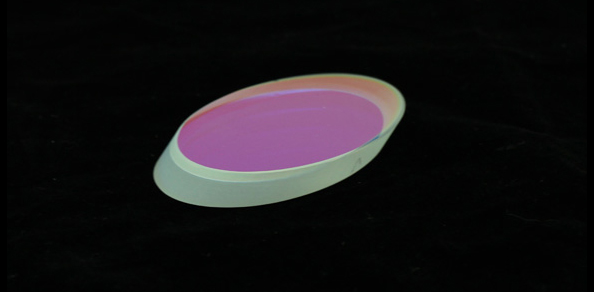

The focusing lens material is ZnSe (arsenic zinc oxide), which is relatively brittle and afraid of falling; When disassembling, be careful not to apply too much force or collide with hard objects.There is an anti reflective film on the surface, which is afraid of pollution, moisture, oil, and scratches; Therefore, it is required to provide dry and degreased air during work,Do not directly handle the lens of the laser cutting machine focusing lens with your hands, as skin oil can cause permanent damage to the surface of the lens.On the contrary, you can wear gloves and their specialized tools for operation. For smaller lenses, using optical tweezers or vacuum tweezers will be more convenient.No matter what method is used to clamp the focusing mirror of the laser cutting machine, it can only be clamped along non optical surfaces, such as the frosted edge of the mirror plaque.