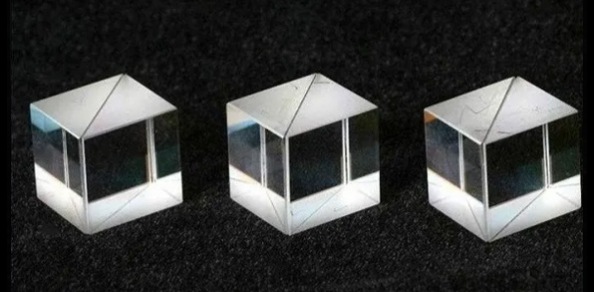

The function of a polarizing prism is to separate the horizontal polarization and vertical polarization of a beam of light, with P polarization completely passing through and S polarization reflected at a 45 degree angle, with the exit direction forming a 90 degree angle with the P light.The ratio of the transmittance of P light to S light is greater than 1000, while ensuring that the transmittance of P light is above 90%.It has the characteristics of low stress, high extinction ratio, good imaging quality, and small beam deflection angle.

The polarizing beam splitter is composed of a pair of high-precision right angle prisms glued together.Below is an introduction to the application of polarizing prisms in laser interferometers.

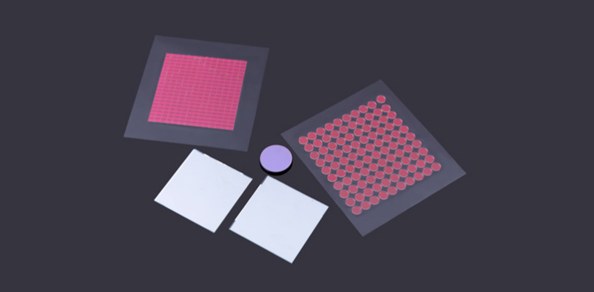

Due to the excellent temporal coherence of lasers, their coherence distance can reach several kilometers,So since the emergence of lasers, the design of laser interferometer lenses using lasers as light sources has always been a focus of attention,Its application scope is constantly expanding, and laser interferometer technology is also constantly developing, resulting in various forms of laser interferometers.

Although there are various forms of laser interferometers, in principle, they can be classified into two basic types: single frequency laser interferometers and heterodyne laser interferometers.

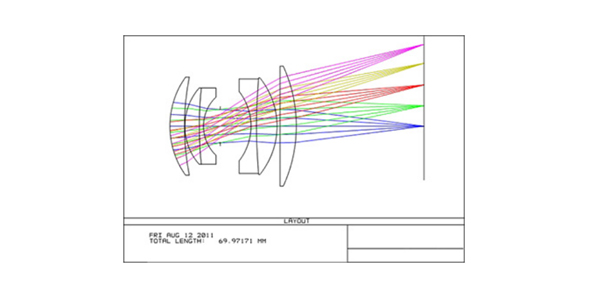

The laser interferometer commonly used for length measurement adopts the Machelson interferometer system,Figure 1 is a schematic diagram of the principle of a single frequency laser interferometer. The beam splitter BS divides the laser into two beams, with one beam directed towards the fixed mirror R,The other beam is directed towards the moving mirror M. When the moving mirror M moves, the reflected light from R and M converges at O to produce interference,Due to the additional phase shift property of the metal film of the spectroscope, the phase difference between the signals received by photodetector D laser lenses 1 and D2 is 90 °, which is used for direction discrimination of the counter.

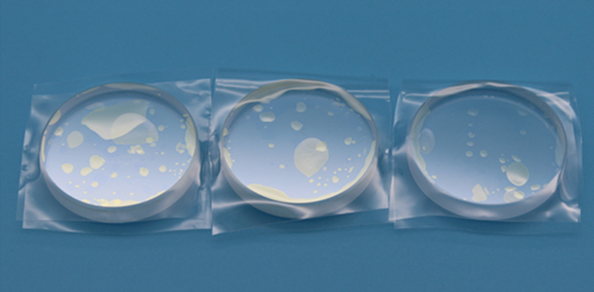

Certain pollutants and lens damage cannot be removed by cleaning, especially film burning caused by metal splashes and dirt. The only way to restore good performance is to replace the lens.

The correct installation method:

During the installation process, if the method is incorrect, the lens may be contaminated.Therefore, the operating procedures mentioned earlier must be followed.If a large number of lenses need to be installed and disassembled, it is necessary to design a fixture to complete the task.A specialized fixture can reduce the frequency of contact with the lens, thereby reducing the risk of lens contamination or damage.

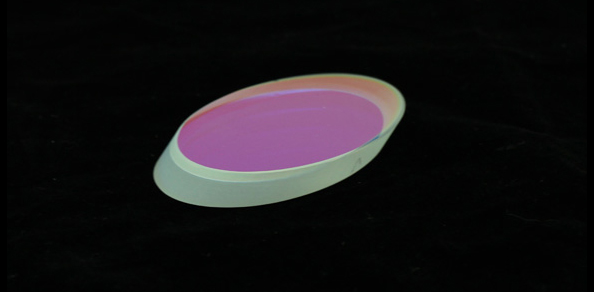

In addition, if the lens is not installed correctly, the high-power laser lens group laser system will not work properly and may even be damaged.All carbon dioxide laser lenses should be installed in a certain direction.So the user should confirm the correct orientation of the lens.For example, the high reflection surface of the output mirror should face inside the cavity, and the high transmittance surface should face outside the cavity,If it is reversed, the laser will not produce laser or produce low-energy laser.The convex surface of the final focusing lens should correspond to the cavity, and the second surface of the lens should either be concave or flat, facing the working surface.If reversed, it will cause the focus to become larger and the working distance to change.In cutting applications, it leads to larger cutting seams and slower cutting speeds.

Reflectors are the third commonly used type of lens, and their installation is also crucial.Of course, it is easy to distinguish the reflective surface of a reflective mirror.It is obvious that the coated side is facing the laser.

Generally speaking, manufacturers will mark the edges to help identify the surface.Usually, this symbol is an arrow, with the arrow pointing towards one side.Every lens manufacturer has a system for marking lenses.Generally speaking, for mirrors and output mirrors, the arrow points towards the high reverse side.For lenses, the arrow points towards the concave or flat surface. Sometimes, lens labels can remind of the meaning of the markings.

Prevention and protection bring returns

When the lens is cleaned and operated correctly, its lifespan and performance will undoubtedly be significantly improved.Taking some preventive and maintenance measures in this article will ensure that the CO2 laser tube works longer and performs better!