The difference between optical glass lenses and other glass lenses is that as a component of an optical system, also known as an optical lens, it must meet requirements such as optical imaging.Its cold processing technology uses chemical vapor phase heat treatment and single piece sodium calcium silicate glass to change its original molecular structure without affecting the original color and transmittance of the glass, making it reach the superhard standard,Ultra hard fire-resistant glass and its manufacturing method and specialized equipment that meet fire protection requirements under high-temperature flame impact.It is made of the following components in a weight ratio: potassium salt vapor (72%~83%), argon gas (7%~10%), gaseous copper chloride (8%~12%), and nitrogen gas (2%~6%).

It includes the following process flow: cutting with sodium calcium silicate glass as the substrate, and cold processing with precision grinding edges→Chemical vapor phase heat treatment of sodium calcium silicate glass after cold processing→Coating the surface of sodium calcium silicate glass with fire-resistant protective film→Perform special physical tempering treatment on the surface of sodium calcium silicate glass.A specialized thermal decomposition gasification equipment is composed of a cylinder body and its cylinder head, as well as a reaction kettle connected to the cylinder head.

There are the following requirements for the quality of optical glass lenses:

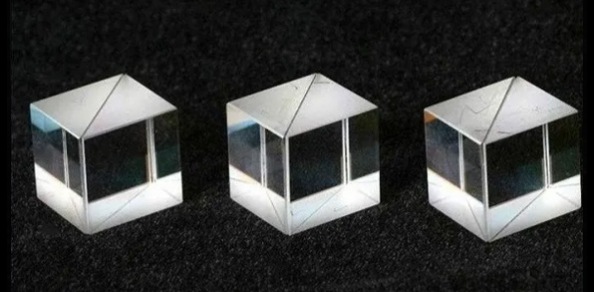

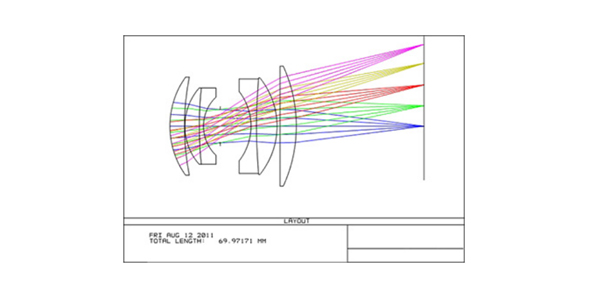

1、Specific optical constants and consistency of optical constants within the same batch of glass

Each variety of optical glass has a specified standard refractive index value for different wavelengths of light, which serves as the basis for optical designers to design optical systems.So the optical constants of the optical glass produced by the factory must be within a certain allowable deviation range of these values, otherwise it will cause the actual imaging quality to deviate from the expected results during design and affect the quality of the optical instrument.At the same time, due to the fact that instruments of the same batch are often made of the same batch of optical glass, in order to facilitate unified calibration of the instruments, the allowable deviation of the refractive index of the same batch of glass should be more stringent than their deviation from the standard value.

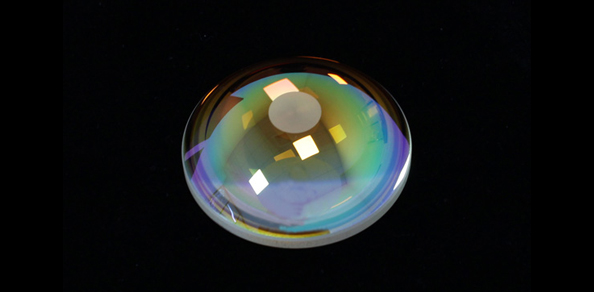

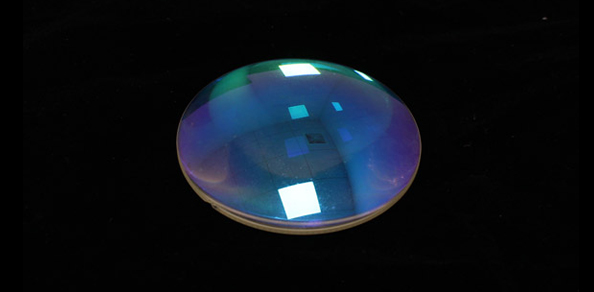

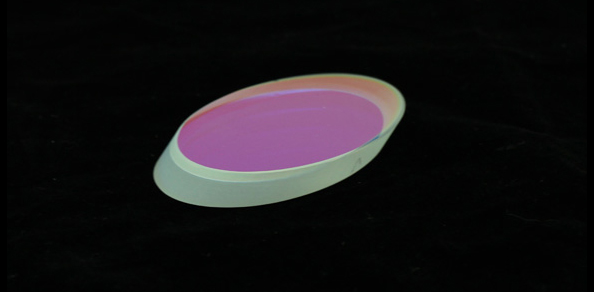

2、Highly transparent

The brightness of optical system imaging is proportional to the transparency of glass, and the transparency of optical glass to a certain wavelength of light is represented by the light absorption coefficient K λ.After passing through a series of prisms and lenses, some of the energy of light is lost at the interface reflection of optical components, while the other part is absorbed by the medium (glass) itself.

The former increases with the increase of glass refractive index, and this value is very large for high refractive index glasses, such as heavy flint glass, where the surface light reflection loss is about 6%.Therefore, for optical systems containing multiple thin lenses, the main way to improve transmittance is to reduce the reflection loss on the lens surface, such as coating a surface anti reflective film layer.

For large-sized optical components such as astronomical telescope objectives, due to their large thickness, the transmittance of the optical system is mainly determined by the light absorption coefficient of the glass itself.By improving the purity of glass raw materials and preventing any coloring impurities from entering the entire process from batching to melting, the light absorption coefficient of glass can generally be reduced to less than 0.01.

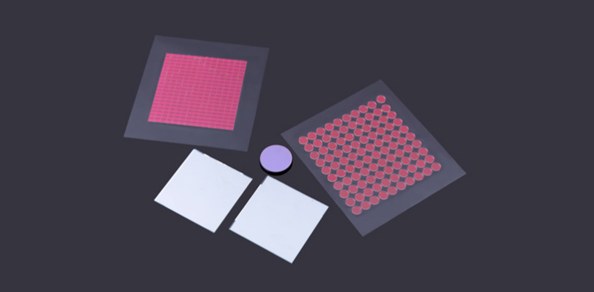

Knowing the process, how can we improve the yield of optical lenses?

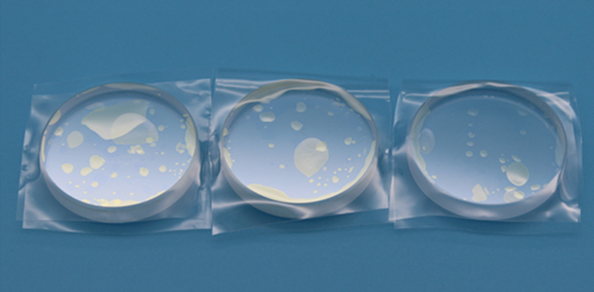

Cutting, CNC machining, clip copying, and precision carving seem to have only a few simple processes,However, the industry's yield rate is only 50%~70%, and the problem of loss in precision processing of optical glass has always been criticized!

Why is this happening? The answer given by professionals is that optical glass has the characteristics of high hardness and brittleness, and its surface is prone to brittle fracture and cracking during processing.

What should I do? Our proposed solution is to develop CNC water-based film stripping protective ink to solve this problem from the source.