一、What are the types of insulated glass?

Insulated glass has special absorption, transmission, and reflection abilities for light and heat. When used in building exterior windows, glass curtain walls, etc., it can achieve significant energy-saving effects.The commonly used insulating glass includes heat absorbing glass, coated glass, and insulating glass.

二、How does heat absorbing glass function?

Heat absorbing glass enhances its absorption of light by adding metal ions or certain substances to the glass, causing it to exhibit certain colors.

The shading coefficient of heat absorbing glass is lower than that of transparent glass, and its shading principle is to reduce its entry into the room by absorbing solar energy through an optical lens.

Disadvantage: Heat absorbing glass will block some of the solar radiation heat regardless of summer or winter,Therefore, it can be used in southern regions where heat prevention is the main focus, but not suitable for northern regions.Heat absorbing glass is actually the absorption of radiation, and the heat absorbed by the glass will eventually be transferred indoors and outdoors.Heat absorbing glass has no selectivity for spectra, which not only reduces sunlight transmission but also hinders the projection of visible light, affecting lighting.

三、How does coated glass function?

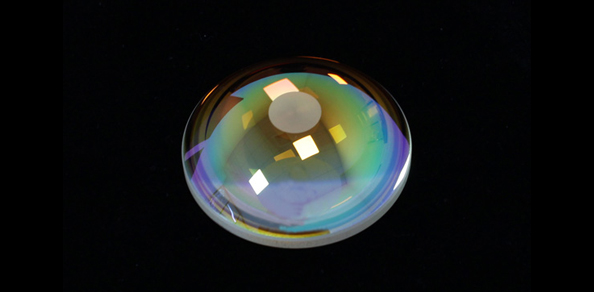

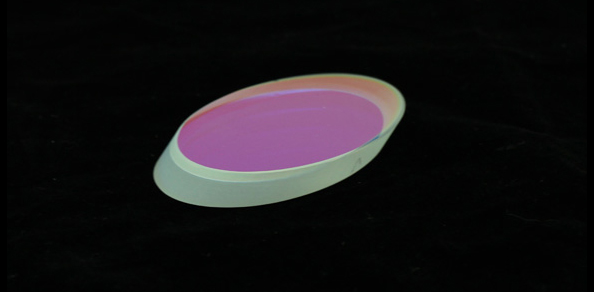

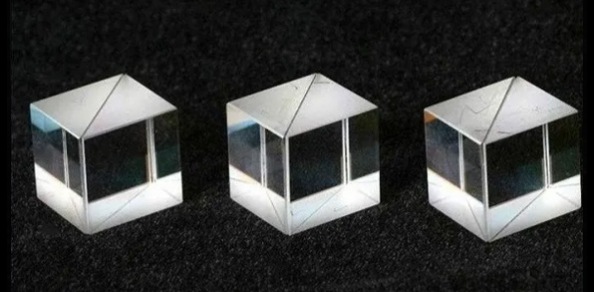

Coated glass is a type of glass that is designed to be coated with one or more layers of metal, alloy, or metal compounds on its surface to alter its properties.According to different characteristics, it can be divided into heat reflective glass and low emissivity glass.

1、Heat reflective glass

Heat reflective glass is coated with a metal film and some interference layers on the surface, allowing the glass product to reflect more solar radiation to achieve shading effect and have rich colors.Heat reflective glass has strong reflection of both visible light and long wave radiation, and its function is to restrict solar radiation from entering indoor environments.

Disadvantages: The thermal insulation of heat reflective glass is almost the same as that of transparent glass,Therefore, laser lenses are not suitable for cold areas with large temperature differences indoors; But in hot areas with strong sunlight, its insulation effect is very excellent.Reflective glass not only reflects solar radiation and heat energy, but also limits the entry of visible light, which can have adverse effects on indoor lighting.In addition, high reflectivity can lead to light pollution, while low reflectivity cannot achieve energy-saving effects.

2、Low-E glass

It is the use of vacuum deposition technology to form a low emissivity (Low-E) coating on the surface of glass.The primary function of Low-E coating is to reflect far-infrared radiation, effectively reducing the heat transfer coefficient of high-power laser glass mirrors;Secondly, it reflects the thermal radiation from the sun and selectively reduces the shading coefficient; Meanwhile, compared to heat reflective glass, low emissivity glass does not impose too many restrictions on the penetration of visible light.

Disadvantage: Due to the poor strength of the membrane layer, it is generally made into insulating glass and not used separately.

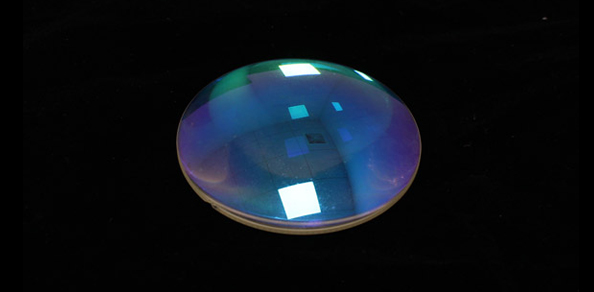

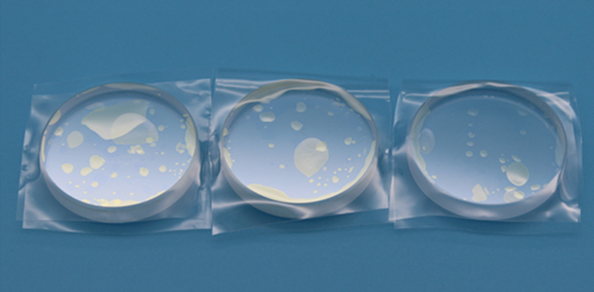

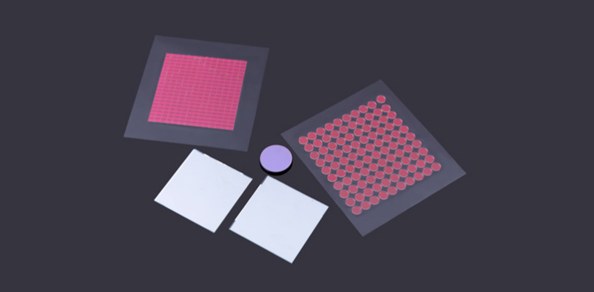

In the process of planar planetary grinding, the uniformity of grinding disc wear is closely related to the grinding quality of optical lenses;By analyzing the motion law of optical lenses in the planar planetary grinding process, a trajectory reflection mirror trace and velocity calculation model for workpiece motion under differential gear system conditions was established, and a Matlab simulation program was developed.

Based on practical production, the trajectory and speed of workpiece motion under planetary gear system conditions were simulated, and the influence law of grinding machine speed ratio on the wear uniformity of grinding disc was determined:When the speed ratio I1<-1.5, the motion trajectory of the lens spreads throughout the grinding disc in a short period of time, and the grinding disc is uniformly worn, resulting in high processing efficiency and quality.Based on simulation results, high-quality optical lenses with thickness consistency less than 0.002mm and parallelism less than 0.002mm were obtained by optimizing process parameters.