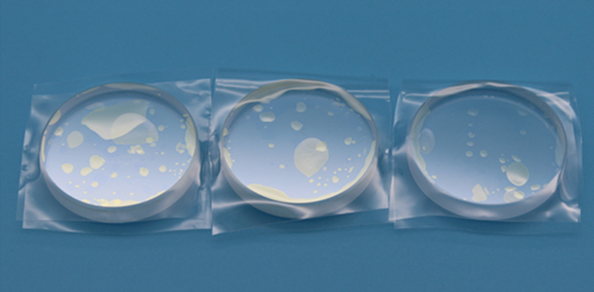

During the installation of laser lenses,if the method is incorrect,the lenses may become contaminated.If a large number of laser lenses need to be installed and disassembled,it is necessary to design a fixture to complete the task.A specialized fixture can reduce the frequency of contact with the lens,thereby reducing the risk of lens contamination or damage.

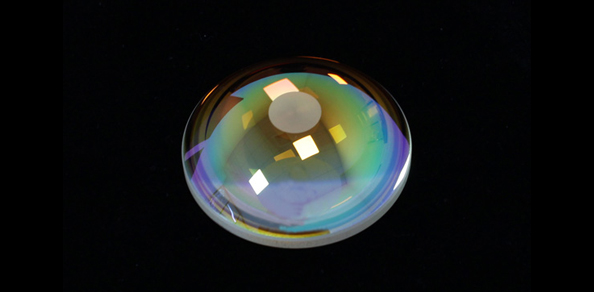

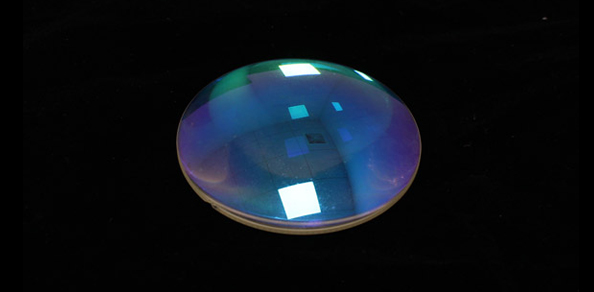

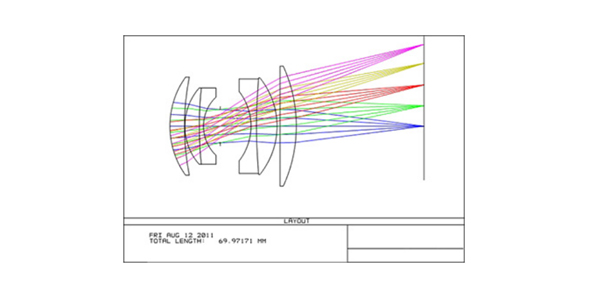

Additionally, if the lens is not installed correctly, the laser system will not function properly and may even be damaged.All carbon dioxide laser lenses should be installed in a certain direction.So the user should confirm the correct orientation of the lens.For example, the high reflection surface of the output mirror should face inside the cavity, and the high transmittance surface should face outside the cavity,If it is reversed, the laser will not produce laser or produce low-energy laser.The convex surface of the final focusing lens should correspond to the cavity, and the second surface of the lens should either be concave or flat, facing the working surface.If the lens design is reversed, it will result in a larger focus and a change in working distance.In cutting applications, it leads to larger cutting seams and slower cutting speeds.

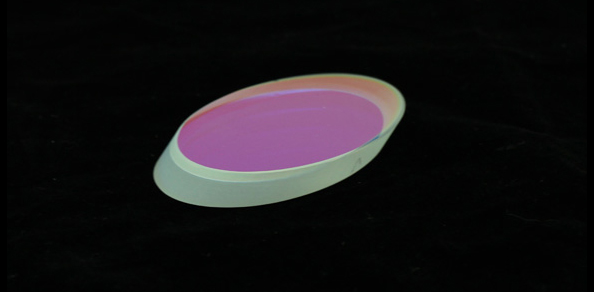

Reflectors are the third commonly used type of lens, and their installation is also crucial.Of course, it is easy to distinguish the reflective surface of a mirror. It is obvious that the coated side is facing the laser.

Generally speaking, manufacturers will mark the edges to help identify the surface.Usually, this symbol is an arrow, with the arrow pointing towards one side.Every lens manufacturer has a system for marking lenses.Generally speaking, for mirrors and output mirrors, the arrow points towards the high reverse side.For lenses, the arrow points towards the concave or flat surface.Sometimes, lens labels can remind of the meaning of the markings.

When using a laser cutting machine to cut organza, we remind you to pay attention,The power should not be too high, otherwise there may be excessive edge melting in the laser lens,Due to the edge melting effect of thermal cutting, it is not possible to cut multiple layers together,Unless it is a highly experienced operator who is familiar with power and processing speed, as well as material density and chemical fiber content,Only with sufficient experience in cutting organza can one consider it, and it is also necessary to cover it with paper during processing to reduce heat radiation.But without such processing experience, it is not recommended to process multiple layers,Generally, it will cause multiple layers of organza to fuse together, and separating them will result in spinning.When encountering these problems, you can communicate with laser tube manufacturers or machine manufacturers to select suitable machine equipment for processing.

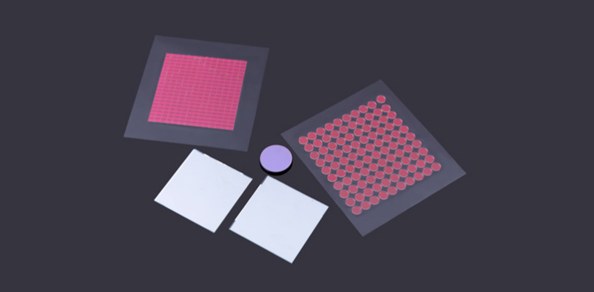

Craft gift laser engraving machine carves dot matrix engraving, resembling high-definition dot matrix printing.The laser head swings left and right, carving a line composed of a series of points each time,Then the laser head moves up and down simultaneously to carve multiple lines, and finally forms the entire image or text with a high-power laser mirror.Scanned graphics, text, and vectorized graphics and text can all be engraved using dot matrix.

Laser engraving machine for craft gifts is different from dot matrix engraving in that vector cutting is performed on the outer contour line of graphics and text.We usually use this mode for penetration cutting on materials such as wood, acrylic, paper, etc., and can also perform marking operations on various material surfaces.

Carving speed of craft gift laser engraving machine: Carving speed refers to the speed at which the laser head moves, usually expressed in IPS (inches/second). High speed brings high production efficiency.Speed is also used to control the depth of cutting. For a specific laser intensity, the slower the speed, the greater the depth of cutting or carving.You can use the engraving machine panel to adjust the speed, or you can use the computer's operating software to adjust the speed.Within the range of 1% to 100%, the adjustment amplitude is 1 mirror%. The advanced motion control system of the motor allows you to achieve ultra fine carving quality even during high-speed carving.

Carving intensity of craft gift laser engraving machine: Carving intensity refers to the intensity of the laser shining on the surface of the material.For a specific carving speed, the greater the intensity, the greater the depth of cutting or carving.You can use the engraving machine panel to adjust the strength, or you can use the computer's operating software to adjust the strength.The adjustment range is 1% within the range of 1% to 100%. The greater the intensity, the slower the speed. The deeper the cutting depth, the deeper it is

Laser engraving machine for craft gifts: The size of the laser beam spot can be adjusted using lenses with different focal lengths.Small spot lenses are used for high-resolution engraving.Large spot lenses are used for lower resolution engraving, but for vector cutting, they are the best choice.