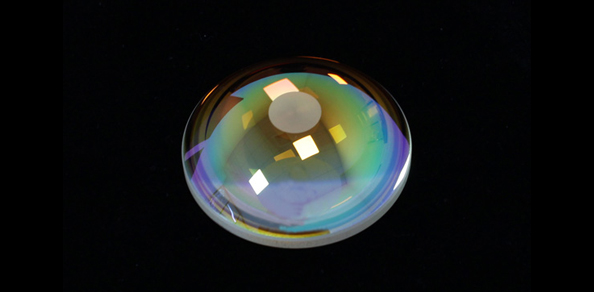

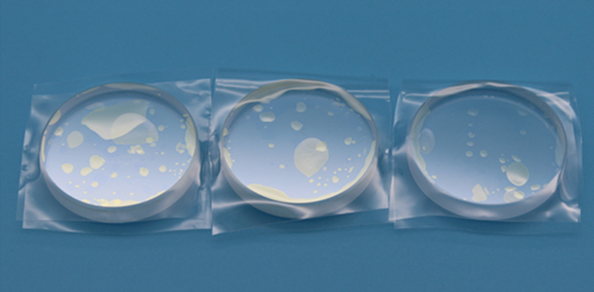

Product size: customizable according to customer requirements

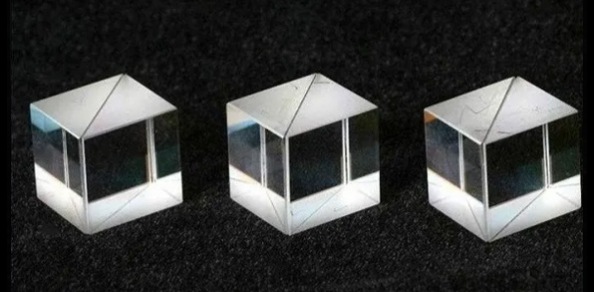

Material Science:BK7,fused silica、ZnSe、ZnS、Ge、Si、GaF2、MgF2、Al2O3、Optical glass, etc

Diameter tolerance:+0/-0.1mm

Thickness tolerance:±0.1mm

Optical aperture:≥90%

Surface quality:20/10

Parallelism:≤3°

Surface accuracy:λ/2 per 1” Dia @632.8nm

Coating parameters:

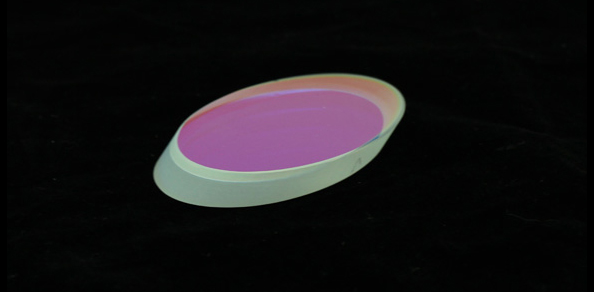

1064nm beam combining mirror:

Average transmittance>99% @ 1064nm, average reflectance>85% @ 650nm.

Coating requirements: First side:T>99%@1064nm,450AOI;

Second side:T>99%@1064nm R>85%@650nm,450AOI。

532nm beam combining mirror:

Average transmittance>99% @ 532nm, average reflectance>85% @ 650nm.

Coating requirements: First side:T>99%@532nm,450AOI;

Second side:T>99%@532nm R>85%@650nm,450AOI

355nm beam combining mirror:

Average transmittance>99% @ 355nm, average reflectance>85% @ 650nm.

Coating requirements: First side:T>99%@355nm,450AOI;

Second side:T>99%@355nm R>85%@650nm,450AOI。

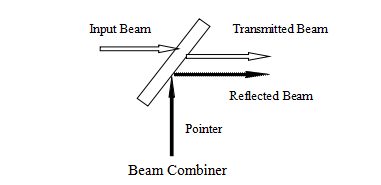

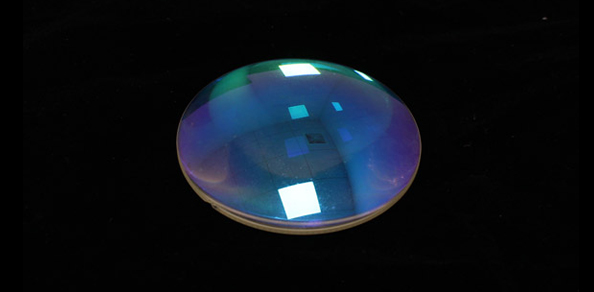

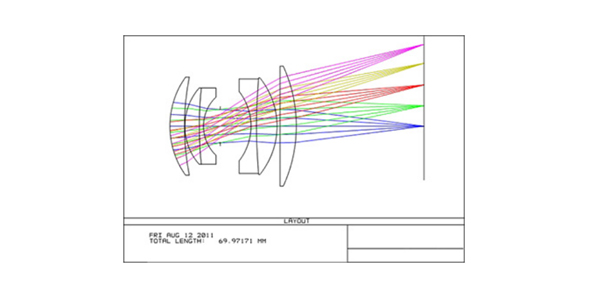

The function of a beam combining mirror is to combine two beams of light into one beam, which is widely used in various laser industries. Generally, the processing laser is combined with the wavelength light used for imaging or indication to form a beam and work at the working position. It is designed to transmit a portion of wavelengths in different bands and reflect a portion. Specific requirements need to be specified by the customer.

Our beam combining mirror is designed to transmit a laser beam with a wavelength of 1064nm when incident at 45 degrees, and calibrate the 1064nm laser beam using a laser beam with a wavelength of 650nm reflected at 90 degrees (visible light).